Takanaka Carpentry Tools Museum graciously gave us permission to present a portion of their 2024 Kanna exhibition brochure, in english. This essay is by Noboru Tsuchida (土田 昇), a legendary tool dealer in Tokyo who works only with Japanese professionals. This excerpt was translated by Togo Miyashita, apprentice of Tak Yoshino at Mount Fuji Wood Culture Society.

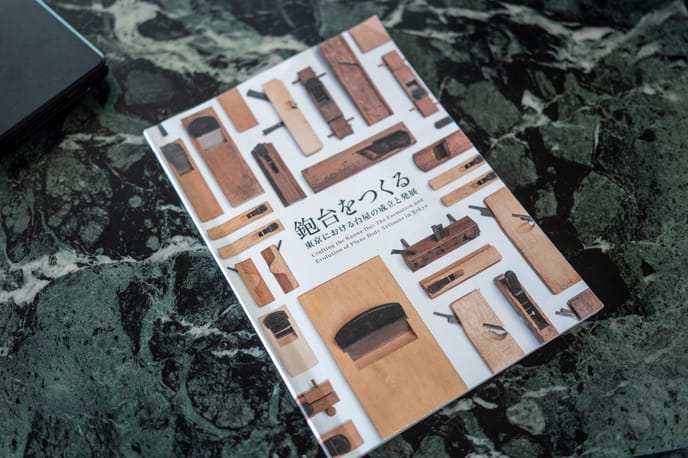

The Kanna Dai, a plane body

治具付切削具と表現すると、いかにも固いイメージのものとなりますが、鉋あるいは台鉋と呼ばれる道具は、切削する鉋刃と、鉋刃が加工対象木材に一定度合で作用するための治具部たる鉋台との二つの要業で成立しています。鋸やノミや玄能、あるいはマサカリ、チョウナ、ヤリガンナの柄も、木製付帯部と解釈できますし、柄のできいかんにより使用感触は変化しますから、機能に大きく関連しますが、鉋台程には切削の質を決定するわけではないでしょう。鉋の機能をひき出すには、つまりより良い鉋削りを実現するためには、研ぎ以上に台の調整が重要であると言われるのはこのためです。

The term “cutting tool with a jig” seems to give the impression of a rigid tool, but a tool called a kanna, or dai-kanna, consists of two essential parts: a blade and a Dai(a jig that allows the blade to work on the wood to a fixed degree). The handles of saws, chisels, hammers, axes, adzes, and Yari-Kanna can also be interpreted as wooden accessories, and the usability of these tools varies depending on the quality of the handle, so they are greatly related to their function, but they probably do not determine the quality of cutting as much as kanna dais. This is why it is said that in order to bring out the function of kanna, in other words, to achieve better planning, the adjustment of the dai is more important than sharpening.

かつて良質な鉋刃を所有しつつ、上手く使いこなせない職人を揶揄する言説はたくさんありました。宝の持ちぐされに類するそんな揶揄に対応するように、銘も知られぬ安価な鉋で見事な削りを実現してしまう職人こそが賞賛され尊敬もされたのです。

In the past, there were many stories that ridiculed craftsmen who owned high-quality kanna blades but could not use them well. In response to such mockeries, craftsmen who were able to achieve excellent sharpening with inexpensive planes that had unknown names were admired and respected.

木工芸作家であり国の重要無形文化財技術保持者(人間国宝)である須田賢司氏の御著者には興味深いエピソードが記述されています。須田氏の先々代、初代須田桑月は鉋削りが上手な指物師で、高価な鉋ではないものを見事に調整して使う、それを見た上等な鉋を持つ大工が鉋の交換をもうしでる、という話なのですが、道具は使い方次第である事を端的に示していますし、私には居職である指物師よりも大きなものを現場で製作する建築分野の職人の方が手間賃が良く、高価な道具を入手できる経済状況にあった事も読み取れ、心に残る記述でした。

An interesting episode is described in a book by Mr. Kenji Suda, a Kogei artist of sashimono(Japanese traditional techniques of making fine joinery) and a holder of the national important intangible cultural heritage technique (Living National Treasure). His great-grandfather, Sougetsu Suda, was a skilled sashimono craftsman and used a non-expensive kanna with great skill and precision, and a carpenter with a superior kanna saw him use it and asked him to replace it. It was a memorable story that clearly shows that tools are dependent on how they are used, and it also shows that craftsmen in the construction field who made large objects on site were paid more for their labor and had access to more expensive tools than the woodworkers, such as the sashimono craftsman.

もちろん鉋刃自体も優秀な鍛冶屋が製作した名品であるに越した事はありません。名品たらしむるべく名人鍛治は研究、精進しているのですから。よって使用者たる職人間に限らず、名人鍛治は注目され、スポットライトをあてられもするのです。比べて鉋台についてはどうでしょう。その鉋台が使用者自らが製作したものであるにしろ、専業化した台屋と呼ばれる職人が製作したものであるにしろ、一般的には刃部程には注目されません。

Of course, the kanna blade itself should also be a masterpiece made by an excellent blacksmith. This is because master blacksmiths study and devote themselves to making their work a masterpiece, which is why they are not only noticed by craftsmen who use the blades, but by the public as well. In comparison, what about kanna dais? Whether the dai is made by the user or by craftsmen who specialize in the manufacture of the dai, it generally does not attract as much attention as the blade itself.

たとえば職人に対して、その使っている鉋を指して「誰が作った鉋ですか」と問えば、必ず鉋刃を作った鍛冶屋の名前が答えとしてかえってくるはずです。鉋台はあくまでも付属品として認識されます。なぜでしょうか。おそらく鉋刃は使用者が自作する事が困難であるからです。鍛治技術は炎をあやつり金属を扱う分野ですから、大工仕事や木工作の延長線上にはありません。火床や金床が完備された場所で鉄や鋼を熱して適正な温度域で的確な打撃の下、刃物を作る熱処理をせねばならず、鉋やノミや鋸を上手く操作する技術ではまかなえません。逆に鉋台はノミと鋸と鉋で製作します。鉋使用者にとって刃部は研磨する事くらいでしかかかわれない対象なのです。よって鉋という道具において鉋刃は特権的な存在となり、その質や作者名が関心の的となるわけです。

For instance, if you ask a craftsman, “Who made this kanna?” referring to the kanna the man is using, the name of the blacksmith who made the blade will surely come back as the answer. The kanna dai is recognized only as an accessory. How is this possible? Probably because it is difficult for users to make their own blades. Forging is not an extension of carpentry or woodworking, as it is a field of metalworking. In a place equipped with a fireplace and an anvil, iron and steel must be heated to the proper temperature range and heat treated under the right hammering to produce blades, which cannot be done with the skill to operate woodworking tools. For the kanna, the blade is an object that can only be sharpened. On the other hand, a kanna dai is made with a chisel, saw, and kanna. Therefore, blades are a privileged part of kanna, and its quality and the name of its maker are the focus of interest.

さてしかし道具は調整の仕方次第、使い方次第のものであり、鉋においては、切削治具たる鉋台のできいかんで機能が決定されます。刃をどれだけ精密に研き上げようが、鉋台の台面整備(台直し)が精度の低いものでは屑すら出ません。

However, tools depend on how they are adjusted and used. In the case of kanna, the function is determined by the quality of the dai, which is the cutting jig. No matter how precisely the blade is sharpened, if the sole is not properly adjusted, not even shavings will be produced.

逆に研ぎが驚く程高精度でなくとも、台面の調整が高度になされていれば、加工対象木材の表面は、精度良くきれいに仕上がります。鉋台の重要性は使用者には周知されています。にもかかわらず鉋台製作者の存在は、おおよそ縁の下の力持ち的あつかいをされてきました。もちろん使用者自身が鉋刃を鉋台にすげ、台調整も行い、見事な削りを披露すれば、使用者は脚光を浴びもしましょう。しかし台製作の専門職、つまり台屋にしかしえない種類の鉋台もあれば、台材の樫の質の見極めにおいては、台入れを桁違いに多く行う彼らにかないようもありません。自らが使うものだけを製作するにとどまる使用者が及ばぬ能力を有しつつ、目立たぬ存在であったのが台屋です。そんな台屋の卓越を見直してみなければ、刃と台というたった二つの要素で構成される切削具の真の姿は見えてこないのではないかと思います。

Conversely, even if the sharpening is not incredibly precise, if the sole is highly adjusted, wood surfaces will be finished cleanly and accurately. The importance of the dai is well known to the users. Despite this, the dai maker's work has been treated as a thankless job. Of course, if users themself set the blade on the dai, adjust the dai, and perform excellent sharpening, they will be in the limelight. However, there are some types of dai that can only be made by a professional dai makers, and there is no one who can match the skill of the craftsman who does an incredible number of adjusting blade insertion and determining the quality of the Kashi Oak, which is the wood used for most of wooden parts of all Japanese tools. Dai makers have a capacity that is beyond the reach of the users, who only produce what they use, and yet have remained a discreet presence. Without a review of the excellence of the dai craftsmen, the true nature of kanna, which is composed of only two elements, the blade and the dai, will not be revealed.